OpenFlexure Microscope

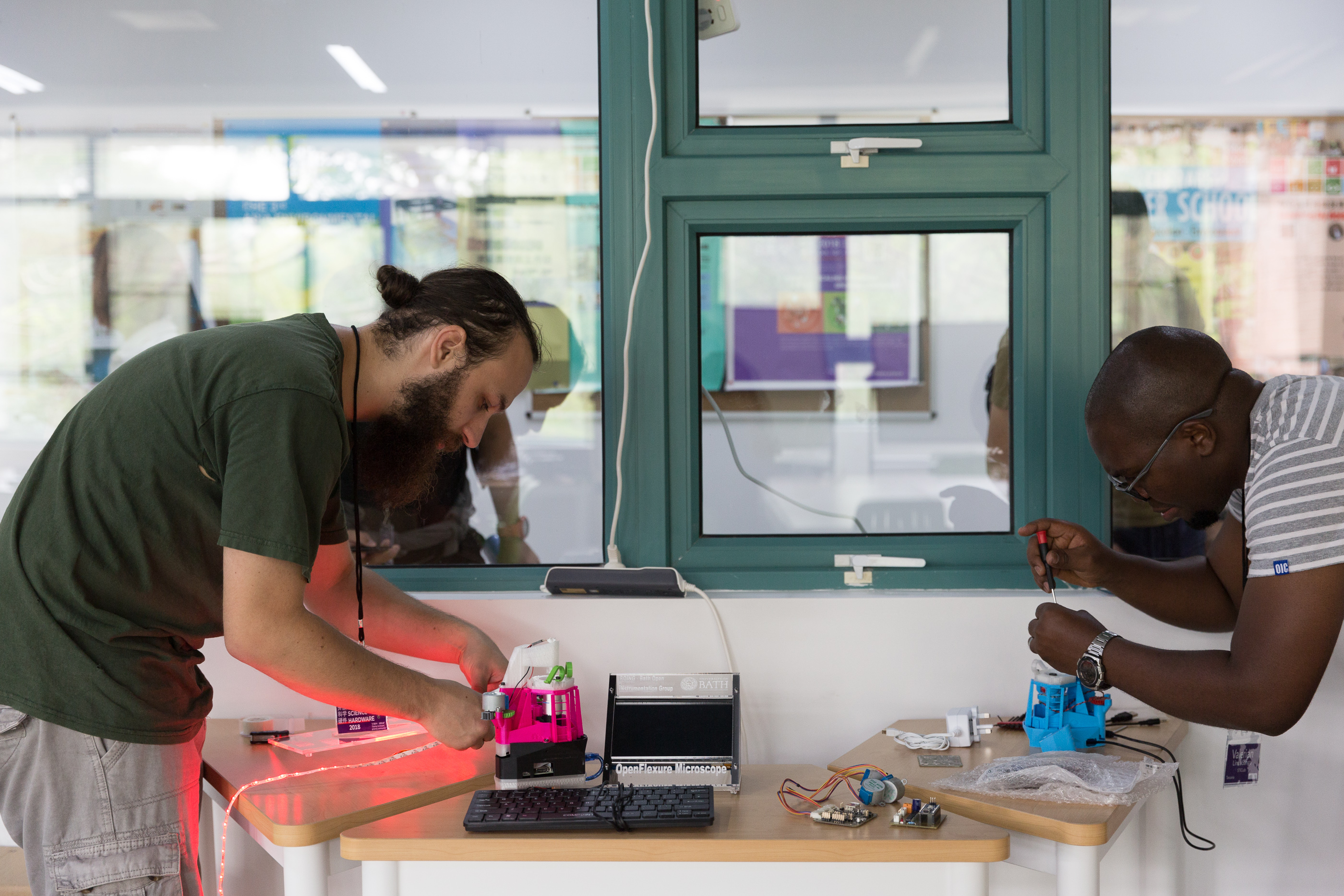

Since 2018 I have been on the core development team of the OpenFlexure Microscope, an open-source laboratory-grade 3D-printed microscope. The microscope is different from many projects which 3D print lab equipment. Instead of attempting to replicate an established design despite limited materials and low surface quality from 3D printing, this project started from the ground up designing a structure that utilises the flexibility of plastic to create a monolithic stage that can only be produced by 3D printing.

Since 2018 I have been on the core development team of the OpenFlexure Microscope, an open-source laboratory-grade 3D-printed microscope. The microscope is different from many projects which 3D print lab equipment. Instead of attempting to replicate an established design despite limited materials and low surface quality from 3D printing, this project started from the ground up designing a structure that utilises the flexibility of plastic to create a monolithic stage that can only be produced by 3D printing.

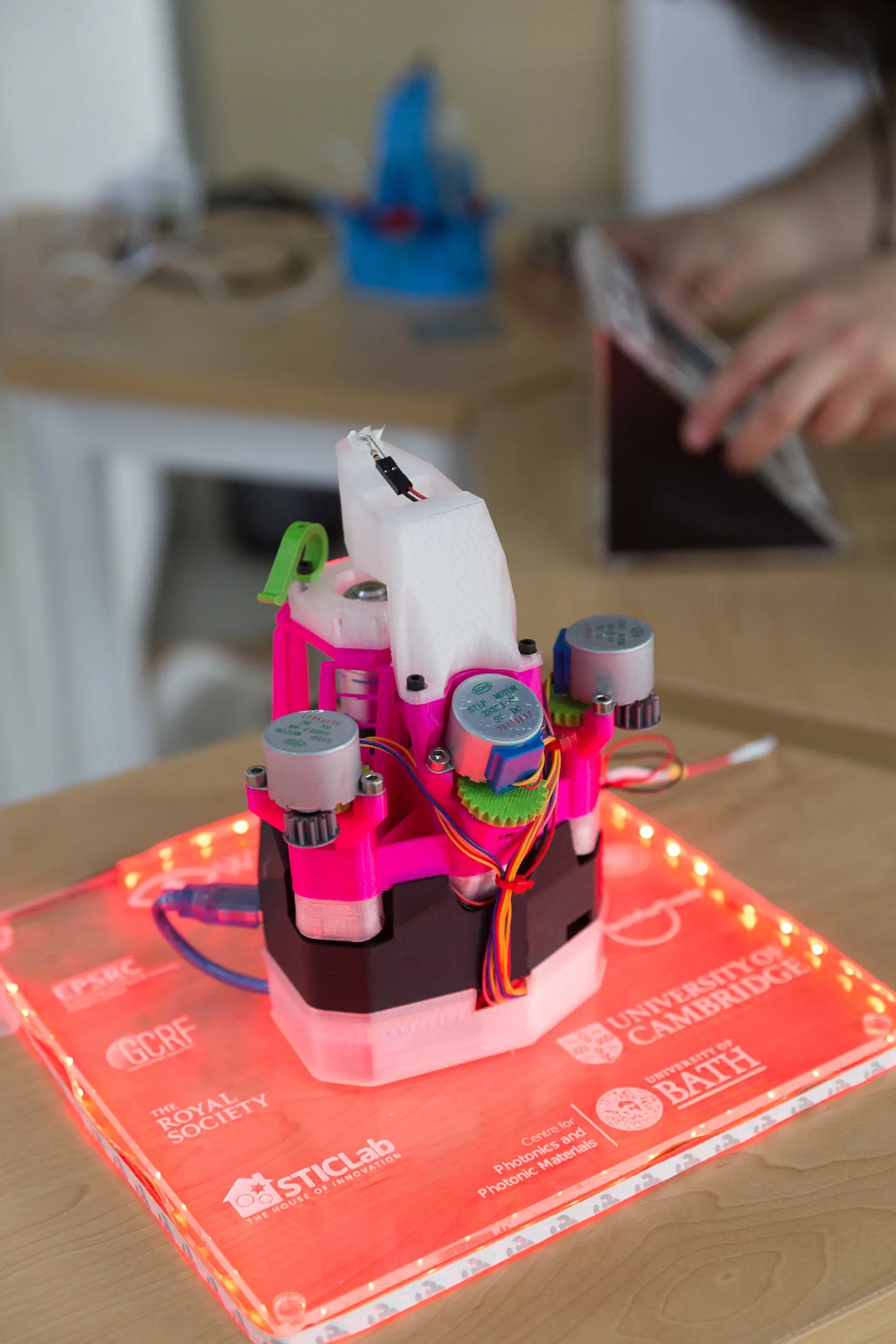

Building a computerised microscope which takes a nice image is actually surprisingly easy with the number of low-cost camera sensors and lenses that are readily available. The challenge to creating a useful microscope is the mechanics. You need to consider how to move the objective to focus on the sample and how to translate the sample. The OpenFlexure Microscope is built around a single 3D printed piece with a number of plastic flexure hinges, which allow precise translation of the sample relative to the objective.

Initially I worked on OpenFlexure as a researcher at the University of Bath. I continued to do work on the microscope while freelancing. Now as the Chief Executive of the Humanitarian Technology Trust I am excited to be working on the OpenFlexure Microscope as our core project.

Initially I worked on OpenFlexure as a researcher at the University of Bath. I continued to do work on the microscope while freelancing. Now as the Chief Executive of the Humanitarian Technology Trust I am excited to be working on the OpenFlexure Microscope as our core project.

The microscope has potential applications for malaria and cancer diagnosis. Since the microscope is robotic, it can act as a slide scanner, taking multiple images and stitching them into a composite (see the interactive image of a cervical smear below).

For the microscope to have real impact in medical diagnosis, we must go beyond proving that it is technically capable. Our aim is to establish a robust quality management process that enables local companies anywhere in the world to manufacture the microscope with consistent and verifiable performance. Each instrument should be demonstrably reliable, delivering the same performance every time it is built and used.

The final hurdle to enable local diagnosis is medical certification. We are working with local manufacturers and regulators to ensure that the microscope can be built and certified in country. This ensures that control remains within each country, while also building the capacity for locally available support and maintenance.