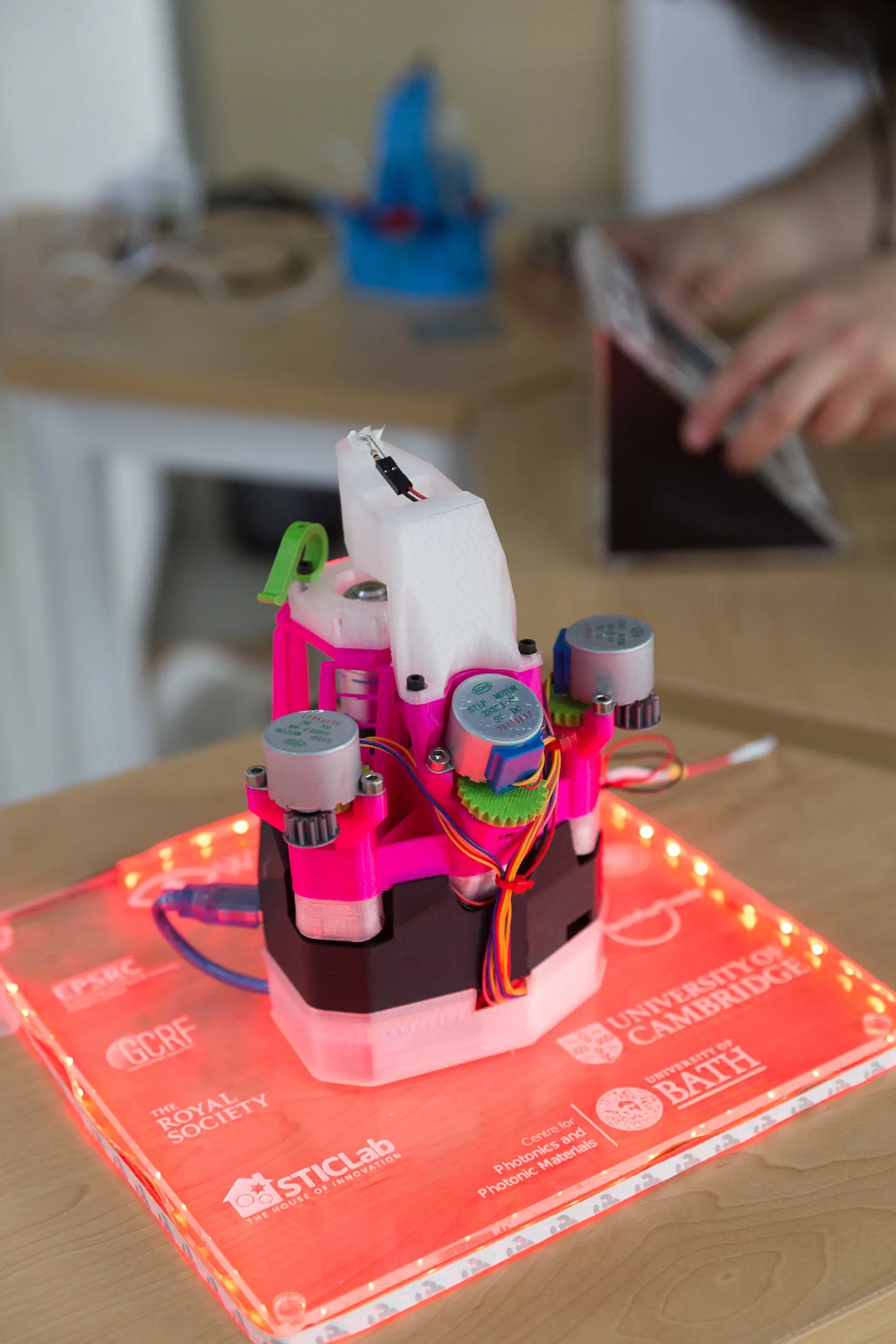

OpenFlexure Microscope

I currently work on the OpenFlexure Microscope, a laboratory-grade 3D printed microscope which is open source. The microscope is different from many projects which 3D print lab equipment. Instead of attempting to replicate an established design despite limited materials and low surface quality from 3D printing, this project started from the ground up designing a structure which utilises the flexibility of plastic to create a monolithic stage that only be produced by 3D-printing.

I currently work on the OpenFlexure Microscope, a laboratory-grade 3D printed microscope which is open source. The microscope is different from many projects which 3D print lab equipment. Instead of attempting to replicate an established design despite limited materials and low surface quality from 3D printing, this project started from the ground up designing a structure which utilises the flexibility of plastic to create a monolithic stage that only be produced by 3D-printing.

Building a computerised microscope which takes a nice image is actually surprisingly easy with the number of low-cost camera sensors and lenses available on the market. The problem with these microscopes is that the time and effort to take that one image makes the microscope incredibly frustrating for educational use, and simply not fit for laboratory use. To build a useful microscope you need to consider how to move the objective to focus on the sample and how to translate the sample. The OpenFlexure microscope is build around a single 3D printed piece with a number of plastic flexure hinges which allow precise translation of the sample relative to the objective.

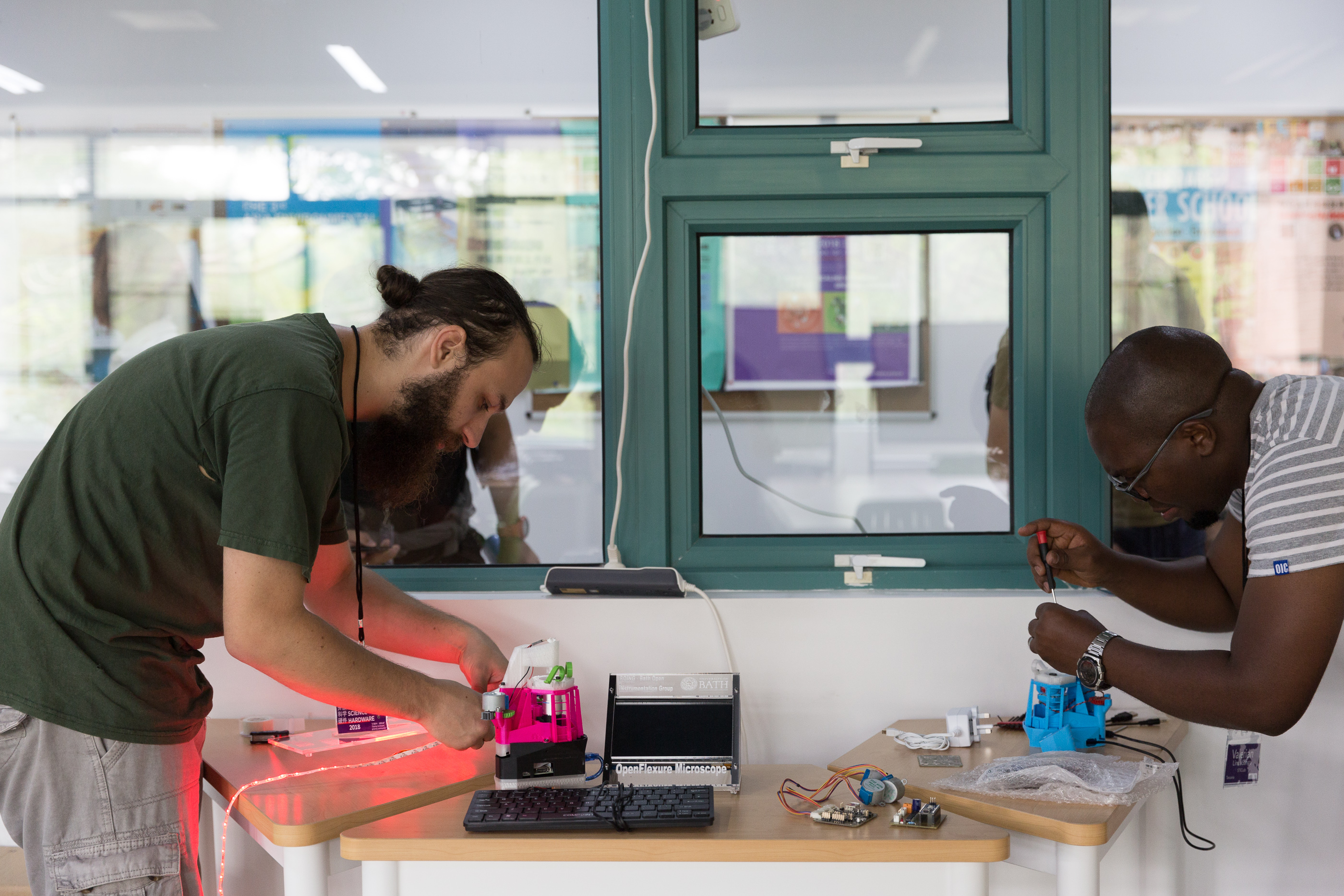

Our recent focus has been on transitioning the project from an academic prototype with wires hanging out into a robust laboratory instrument that can be trusted to do its job day in day out. Our project partners BTech in Tanzania are currently producing microscopes for research and educational use and are working towards producing an certified diagnostic version.

Our recent focus has been on transitioning the project from an academic prototype with wires hanging out into a robust laboratory instrument that can be trusted to do its job day in day out. Our project partners BTech in Tanzania are currently producing microscopes for research and educational use and are working towards producing an certified diagnostic version.